Why your business needs better supply chain processes

Even the most talented teams can’t outrun weak supply chain processes. No matter how skilled your people are, if the workflows they rely on are clunky, unclear, or built on workarounds, performance will stall, costs will rise, and service levels will slip.

In modern supply chains, processes are the engine of your operation. When they’re designed well, everything runs smoother. Work gets done faster, handovers are clean, training takes less time, and issues are easier to spot and fix. But when processes are misaligned or overly complex, your team spends more time chasing problems than solving them.

The challenge is that most processes aren’t deliberately designed. They’re inherited, patched together over time, and shaped more by habit than intent. That leads to friction, delays, and missed opportunities, and it creates unnecessary stress across your business.

Let’s break down how to design and implement supply chain processes that truly work, processes that empower your team, scale with your business, and deliver consistent, measurable results. Using a proven 9-stage framework, SCOPE-AREA, we help you build supply chain processes from the ground up or transform the ones already in place, processes that are practical, robust, and set up to keep your operations running smoothly and efficiently, even under pressure.

The cost of broken supply chain processes

Most businesses don’t set out to create poor supply chain processes, but over time, that’s where they end up. What begins as a simple workaround or a quick fix slowly becomes the norm. A spreadsheet here, an extra approval there, a manual step “just in case”, and before you know it, the process is overcomplicated, unclear, and causing delays and confusion.

People stop following the steps because they no longer make sense. Teams lean on tribal knowledge instead of clear, documented workflows. And when something breaks, no one’s sure where the failure happened or who’s responsible for fixing it.

That’s the real cost of broken supply chain processes: not just missed deadlines or lost efficiency, but wasted time, eroded trust, and a constant cycle of reactive problem-solving that drains your team’s focus and energy.

It usually comes down to three core problems:

1. Built for compliance, not performance

Many supply chain processes are designed to tick boxes, meeting ISO standards or passing customer audits, but they do little to help teams work faster or smarter. They might look good on paper, but in practice, people follow them just to stay compliant, not because they genuinely improve how work gets done.

2. No clarity on designing real value

Most teams can’t separate value-added (VA) work from non-value-added (NVA) or necessary non-value-added (NNVA) tasks. Without that understanding, they hold on to unvaluable steps and overlook the ones that truly matter. And with unclear ownership, no one’s responsible for fixing it.

3. Quick fixes instead of long-lasting redesign

Rather than stepping back to rethink and redesign the full flow, businesses often just bolt on extra steps to solve surface-level issues. Over time, these patches pile up, making the process more fragile, more complex, and far more prone to breaking down.

If your team constantly has to work around the process to get things done, the problem isn’t the people, it’s the supply chain processes design.

The red flags of broken supply chain processes

When a process doesn’t work, the symptoms are easy to see but often ignored:

- Inconsistent results across teams

- Unclear roles and blurred accountability

- Missed deadlines and slow decision-making

- Manual workarounds and duplicated effort

- Underused or completely overlooked integrated systems

- Lengthy, inefficient onboarding

- Constant reactive problem-solving and last-minute fixes

These aren’t minor setbacks, they create systemic drag across your entire operation. Worse still, they erode critical visibility, masking the underlying issues and making it nearly impossible to pinpoint root causes amid the noise.

Ineffective processes also increase operational risk. Decisions get delayed, data integrity weakens, and lines of accountability become blurred. When failures occur, you’re left guessing rather than knowing.

High-performing supply chain processes

Strong supply chain processes improve workflow efficiency, reduce operating costs, cut waste, and give teams the clarity and structure to execute with confidence. Effective design starts with a disciplined review of each task, classifying it as value-added (VA), non-value-added (NVA), or necessary non-value-added (NNVA). Any step that fails to deliver value or meet essential control or compliance requirements adds unnecessary cost without delivering any benefit.

What strong supply chain process design delivers

Clarity

Everyone understands their role, what’s expected, and what comes next. No confusion, no wasted time.

Consistency

Workflows run the same way across teams, sites, and functions, driving reliability and alignment.

Visibility

You get clear oversight of performance, can identify bottlenecks early, and know exactly where time, money, or resources are being lost.

Control

Defined checkpoints, clear ownership, and built-in governance keep things on track and stop issues from slipping through the gaps.

Scalability

Processes flex and grow with the business, without adding unnecessary layers or overhead.

Usability

Simple, practical workflows that are easy to follow and quick to train, enabling people to work efficiently without second-guessing.

When you address the root causes behind failing supply chain processes, you will notice improvements in clarity, consistency, and control across your operations.

- Smoother handovers, with clear accountability

- Faster, more confident decision-making, with fewer errors

- Shorter onboarding and easier training

- Cleaner, more reliable data and sharper reporting

- More time focused on value-driving activities, less time wasted on rework

- Stronger alignment and collaboration across teams and functions

Creating sustainable, high-impact processes

We partner with businesses to move beyond operational guesswork, eliminate systemic inefficiencies, and establish high-performance, resilient supply chain operations. Whether you’re undertaking a full process transformation or optimising workflows that are no longer fit for purpose, our SCOPE-AREA framework provides a proven, structured methodology to engineer processes that are not only built for precision and scalability, but also embedded for sustained execution.

If your teams are still depending on workarounds, manual interventions, or institutional memory to keep operations running, it’s a clear signal that your processes need a strategic redesign.

Our case study demonstrates exactly how we support organisations in architecting supply chain processes that drive measurable impact, strengthen governance, and deliver lasting operational advantage using the SCOPE-AREA approach. It’s time to make your processes an asset, not a liability.

Example case study

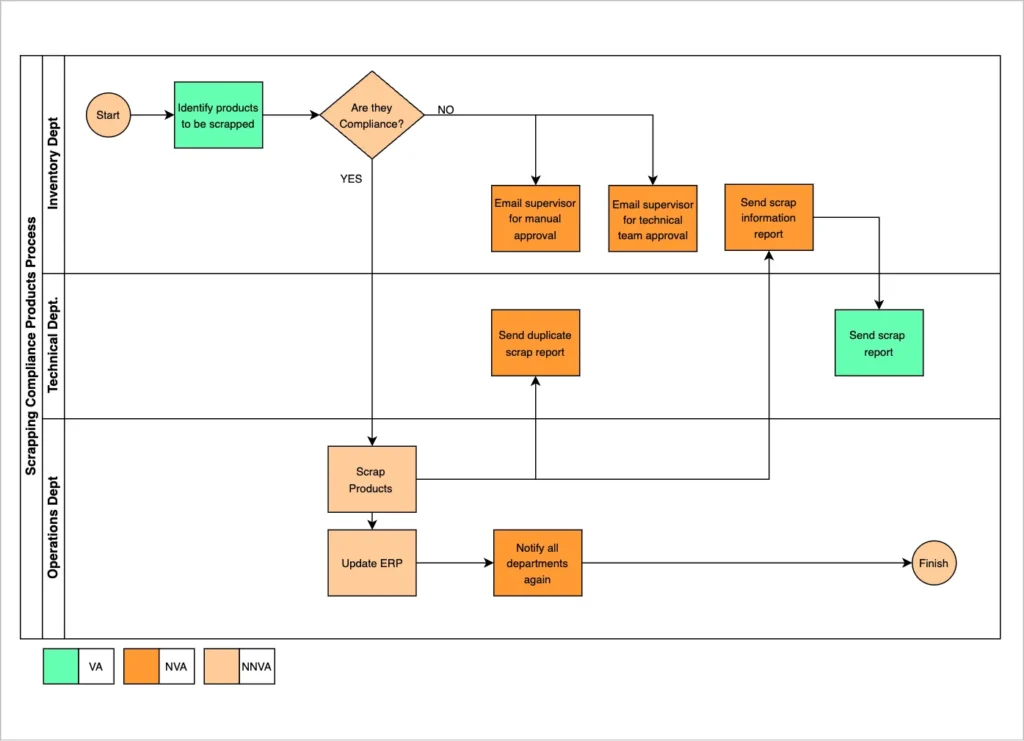

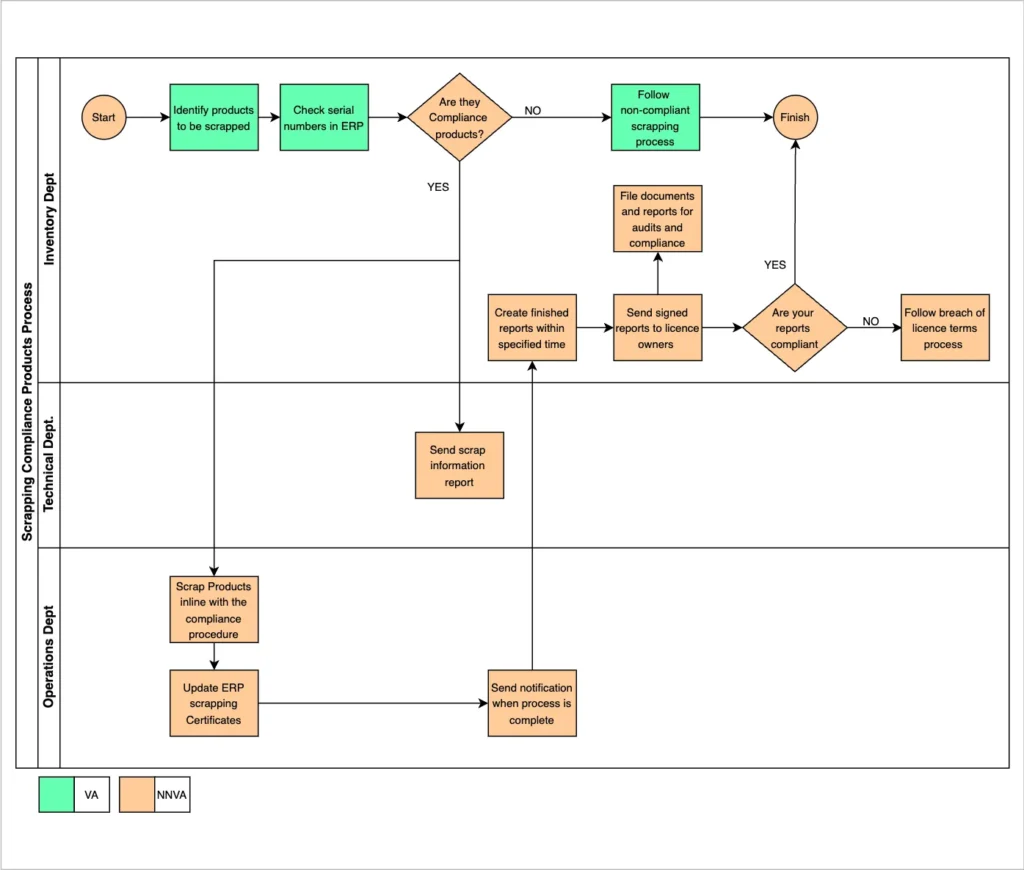

This example compares two approaches to scrapping compliance: a poorly designed process (pic1) and a best-practice version (pic2). By visually mapping and analysing each, we show how inefficiencies drive cost and delay, and how effective design eliminates waste.

1. Weak scrapping compliance process

The diagram below (pic1) illustrates a weak scrapping compliance process. It features excessive manual approval, duplicated effort, unclear roles, and wasteful reporting. Each step is colour-coded by value classification: Green = Value-Added (VA), Orange = Necessary Non-Value-Added (NNVA), and Red = Non-Value-Added (NVA).

Why this process fails

x Too Many Approvals (NVA): Unnecessary supervisor and technical sign-offs delay progress.

x Repetition (NVA): Duplicate scrap reports waste time and create inconsistency.

x Manual Compliance Reporting (NNVA): Needed for audit but done inefficiently.

x Manual Notifications (NVA): Alerts sent manually instead of through system triggers.

x Misaligned Finish: Process ends after reporting, not action.

x Poor Role Clarity: Multiple departments touching the same decision with no added insight.

1. Strong scrapping compliance process (best practice)

This diagram below (pic2) shows an optimised, streamlined scrapping process. Each step is designed to either deliver value directly or meet necessary compliance requirements with minimal waste. Ownership is clear, approvals are built into workflow rules, and communication is system driven.

Why this process works

- Clear Ownership: Inventory, Technical, and Operations only do what they’re meant to.

- Only Necessary NNVA: Compliance steps are limited to those required, nothing more.

- Automation Ready: ERP handles updates and notifications automatically.

- Single Reporting Cycle: No loops or rework, report once and done.

- Practical Finish: The process ends after the job is complete, not after extra admin.

- Audit Ready: Everything tracked, nothing over-handled.

The SCOPE-AREA framework

To help businesses build better processes, we use a 9-stage approach called SCOPE-AREA. It’s practical, grounded in real operations, and built to deliver lasting change, not just short-term fixes.

Study the current state

See how the process works today, from every angle

We start by mapping what’s really happening, not what’s supposed to happen. That means talking to the people who do the work, tracing every step, and looking at how data moves (or doesn’t).

Example: You map how Purchase Orders are raised, from request to approval. You find four different systems in use, two manual spreadsheets, and inconsistent timelines across teams.

Capture pain points and inefficiencies

Spot what’s slowing you down and where improvement matters most

We find the friction, bottlenecks, handover gaps, unclear ownership. Tasks are classified into value-added, non-value-added, and necessary non-value-added.

Example: You spot delays because approvals sit in inboxes for days. No one tracks aged POs. You also find planners duplicating requests because they don’t trust the visibility in the system.

Optimise and redesign

Build a simpler, faster, more effective process

We cut clutter, simplify flows, and rebuild cross-functional processes to be easier and more reliable.

Example: You cut two approval steps, create a single shared tracker, and rebuild the PO process around your ERP system. Approval rules are set by category and value, not guesswork.

Prepare ownership and measures

Make the process accountable and trackable

We assign ownership, define measures, and set rules for reporting and escalation.

Example: You assign clear ownership for each approval stage and set a 24-hour SLA. A dashboard shows stuck POs and who’s responsible, so nothing falls through the cracks.

Enable through training and testing

Get your team ready to use the process properly

Trial runs and clear training materials help ensure your people know what to do, and when.

Example: You walk the team through the new flow using real examples. You tweak one step where finance flagged an edge case. Training is done using a simple one-pager with screenshots.

Activate with support

Launch the process and keep it on track

Structured rollout with support prevents drift and addresses early-stage issues fast.

Example: You launch the new process on a Monday with support in place. For two weeks, you track execution daily, fix issues fast, and keep communication clear and constant.

Review with data and feedback

Keep the process performing in the real world

We use KPIs and feedback loops to track performance and catch issues early.

Example: Two weeks in, you review performance. Approval times dropped by 40%, and there’s higher system usage. Feedback shows people still flag unclear escalation rules, so you fix them.

Enhance through structured improvement

Improve without overhauling

Small, regular tweaks keep the process relevant and efficient.

Example: You add automated email alerts for stalled requests and link order status to a central dashboard. The team suggests reducing weekly meetings because issues are now visible.

Adapt as the business evolves

Stay in control as things grow or change

We build flexibility so processes can evolve without needing full redesigns.

Example: As you onboard new suppliers and introduce a new category, you adjust the approval thresholds and tracking views, without redesigning the full process.

Conlusion

If your team is still relying on workarounds, manual fixes, and institutional memory to keep operations moving, you’re not just losing time, you’re steadily losing control over your supply chain. Without robust, well-designed processes, tasks slip through the cracks, accountability becomes blurred, and performance becomes reactive rather than strategic.

Strong, intentional supply chain processes deliver clarity across roles, reduce unnecessary costs, strengthen governance, and create a scalable foundation that supports growth without adding complexity or chaos. When your processes are clear, aligned, and embedded, your teams can focus on delivering real value, not managing exceptions or patching gaps.

Are your current processes setting your business up to thrive, or are they quietly holding you back?