What actually works when short-term solutions keep failing

Many supply chains operate in reactive mode. When something breaks, the instinctive response is to patch it up quickly and move on. Adjust a reorder parameter, add extra safety stock, deploy a new forecasting module. These interventions create a perception of responsiveness, but in truth, they only delay the recurrence of the same issue under a different label.

The underlying problem remains unresolved. It is concealed by short-term fixes. Without targeting the root cause, operational symptoms continue to reappear and frequently result in higher costs.

This article walks through how a structured root cause approach, built around the DMAIC framework, can move organisations from reactive problem-solving to long-term, systemic resolution. Through a real-world example, we demonstrate how a manufacturer regained control over compliance-driven stock write-offs, avoided further financial loss and embedded sustainable improvement into daily operations.

The limitations of quick fixes

When operational issues arise, time pressure often drives short-term actions. These responses are rarely guided by data, structured thinking or cross-functional collaboration. Instead, they are shaped by management pressure, urgency, assumptions and isolated decision-making. None of which support long-term success.

Quick fixes typically lead to three ongoing problems:

1. Covering symptoms instead of fixing the process

Temporary workarounds hide the real issue. They mask failures in process, system logic or communication rather than addressing them directly.

2. Repeat waste and rising operational cost

The same issue comes back in different forms, draining time, stock and management capacity with every cycle.

3. Breakdown in team trust and process discipline

When problems keep returning, teams stop trusting the system. They create their ownworkarounds, which adds variation, inconsistency and even more risk.

In complex supply chains, operational problems are rarely caused by a single function. Inventory imbalances may be triggered by forecasting misalignment, procurement timing, planning assumptions or project delays. When problem-solving is siloed, the true cause is never addressed, and the issue evolves rather than disappears.

Establishing root cause thinking

Root cause analysis is not an event. It is a way of working. It demands a shift in mindset from “who made the mistake”to “what within the process allowed this to occur.” The objective is not to assign blame, but to identify and correct the structural or procedural weakness that made the failure possible.

One method that supports this way of thinking is the Five Whys. This technique guides teams to look beyond symptoms and uncover the foundational causes that drive repeat incidents. It is a simple but effective tool when used in combination with other structured analysis methods such as process mapping, data segmentation, Pareto analysis or cross-functional interviews.

However, root cause thinking must be implemented with a repeatable structure. That is where the DMAIC methodology offers practical value.

Why the DMAIC framework delivers results

DMAIC stands for Define, Measure, Analyse, Improve and Control. Originally designed for quality and process improvement environments, this framework is highly effective in supply chain settings where root cause analysis is often overlooked or inconsistently applied.

Each stage of DMAIC focuses on solving problems in a disciplined, data-driven and cross-functional way. It ensures the organisation does not jump to conclusions or implement unproven solutions. Instead, it systematically investigates the issue, verifies its scope and resolves the failure at the point where it originates.

To illustrate how DMAIC works in real operational environments, we examine a high-impact example from a manufacturer that faced escalating losses due to compliance-driven inventory scrapping.

Example case study

DEFINE – Clarifying the problem statement

A high-tech manufacturer supplying parts to aerospace clients was scrapping fully functional stock due to compliance lapses. Certificates of Conformance (CoCs) had expired. Shelf-life tracking was inconsistent. Documentation was incomplete. Although the inventory was physically usable, it no longer met contractual requirements and had to be scrapped under strict regulatory terms.

In the first incident, the business wrote off over £500,000 in compliance-sensitive parts. Six months later, another £300,000 followed. Despite local efforts to address the issue, such as implementing manual expiry date tagging, the problem persisted. Scrap rates increased, and inventory losses mounted.

The business had not defined the problem in structured terms. It was treating individual symptoms without understanding what systemic failure allowed these materials to degrade past their compliant lifespan.

MEASURE – Quantifying the operational impact

To drive meaningful improvement, the organisation first needed to quantify the issue with clarity and precision. This was not simply a case of expired stock. It was an operational breakdown with financial, reputational and customer service implications.

Key performance indicators included:

- £800,000 in scrap losses over a twelve-month period

- Over 90% of the scrapped items were fully functional but deemed non-compliant

- Lead times for replacement parts caused knock-on delays in downstream production

- Warehouse utilisation increased due to holding at-risk stock beyond useful life

- Manual intervention efforts failed to reduce scrap incidence across quarters

The team identified that most losses occurred on project-driven materials, particularly those with complex certification and documentation requirements. The issue was not limited to one department. It involved Planning, Procurement, Quality Assurance and Project Management.

MEASURE – Quantifying the operational impact

To drive meaningful improvement, the organisation first needed to quantify the issue with clarity and precision. This was not simply a case of expired stock. It was an operational breakdown with financial, reputational and customer service implications.

Whys example

1. Why was the stock scrapped?

Because the (CoC) expired.

2. Why did it expire before the stock was used?

Because the material sat in inventory for too long.

3. Why was it procured so far in advance of actual need?

Because procurement followed the original project schedule.

4. Why was the project delay not communicated to procurement?

Because project updates were not systematically shared with planning.

5. Why was there no automated visibility of project changes?

Because compliance risk and schedule updates were not built into MRP logic, ERP configuration or day-to-day planning workflows.

Root Cause: The business lacked a structured workflow that connected project delays, compliance requirements and planning data. As a result, stock was procured too early, held too long and ultimately scrapped due to expired Certificates of Conformance.

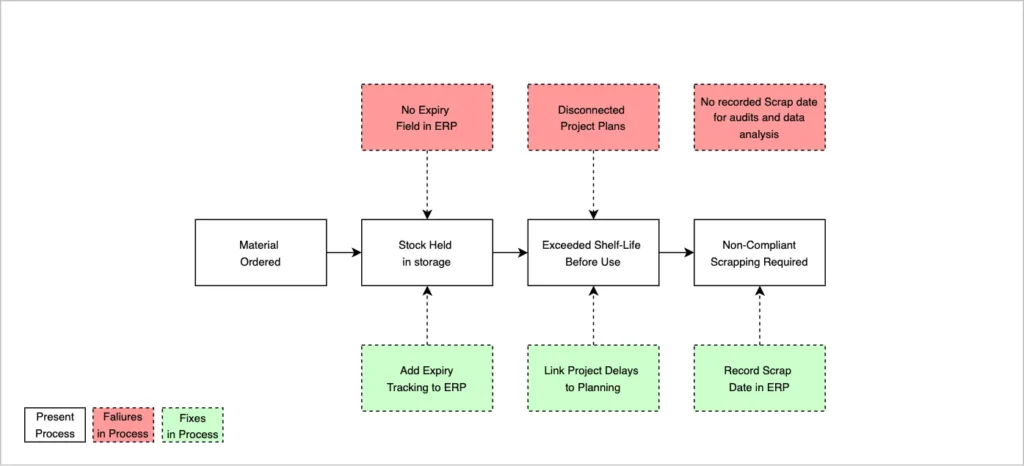

Three major process gaps were confirmed

- No expiry or compliance tracking in the ERP system

- No protocol for communicating project delays across functions

- No integration of compliance requirements within material planning logic

IMPROVE – Implementing targeted process fixes

Armed with a clear root cause, the business focused improvement efforts on structural changes rather than surface fixes.

Actions taken included

- Updating the ERP system to include expiry dates, shelf-life tracking and Certificates of Conformance flags

- Creating automated project milestone triggers that alerted Planning and Procurement of timeline changes

- Integrating Quality Assurance into weekly planning reviews to proactively assess compliance-sensitive stock

- Revising standard operating procedures to include mandatory checks on lead times, expiry status and certification windows prior to release of project-driven purchase orders

These changes were not isolated system adjustments. They were integrated process changes that connected data, decision-making and accountability across functions.

CONTROL – Preventing recurrence through governance and ownership

To ensure long-term control, the improvements were formalised into daily operations. Control measures were integrated to detect early warning signs, enforce compliance and reinforce ownership.

The following steps were implemented

- Assigning formal ownership of compliance monitoring to Quality Assurance (QA) with shared oversight from Planning

- Developing automated alerts in ERP to flag items nearing expiry, based on a rolling 90-day window or adjusted for longer supplier lead times.

- Introducing cross-functional training, e-learning and onboarding for teams managing compliance-sensitive materials.

- Integrate project delay notification protocols into the Project Management Office (PMO) governance framework

- Reviewing compliance triggers twice a year as part of internal audit and continuous improvement cycles.

By designing the controls around the failure point, not the symptom, the organisation ensured that the process failure could not resurface unnoticed.

Compliance scrap flow: mapping failures, improvements and controls across Analyse, Improve and Control

Tangible results

Within six months of implementing the DMAIC-based improvement programme, the business achieved measurable operational and financial gains:

- Compliance-related scrapping dropped by over 90%

- £1.2 million in at-risk inventory was reallocated before becoming obsolete

- QA and Planning transitioned from reactive escalation to proactive management

- Project managers gained visibility into stock impact from delay decisions

- The ERP system now provided actionable alerts and traceability in real time

The improvements were not limited to compliance outcomes. The entire material planning discipline became more accurate, data-driven and aligned to project realities.

Embedding root cause into business rhythm

One-off improvement projects do not transform operations. Long-term impact comes when root cause thinking becomes part of how the business operates.

To embed this approach, organisations must

- Include root cause reviews in S&OP or operational governance meetings

- Frame cross-functional problem-solving around process breakdowns, not individual errors

- Document corrective actions with ownership, metrics and timeframes

- Incorporate root cause methodology into onboarding for planners, buyers, QA, product management and project teams

By making structured problem-solving part of daily operations, companies improve not only resolution speed but also problem visibility. This drives performance, trust and resilience across the end-to-end supply chain.

Final recommendations

A supply chain that functions reactively cannot scale, protect margins or meet customer expectations reliably. Quick fixes might create the appearance of progress, but they fail to solve the actual problem.

Root cause methodology, executed through frameworks like DMAIC, enables businesses to

- Replace reactive response with data-driven control.

- Uncover and address structural weaknesses in planning, procurement and project execution

- Reduce operational waste, from excess stock to repeat quality failures

- Build functional alignment across departments with shared accountability

What this means for your business

Strong supply chains are not held together by reactive decisions or short-term workarounds. They are built on clear processes, disciplined execution and the ability to fix what causes problems not just manage the fallout.

If your team keeps solving the same issues, the problem is not the people. The problem is the process. Root cause thinking is not a one-off task or a theoretical workshop. It is a disciplined approach to running the business. It brings clarity, accountability and measurable results across planning, procurement, quality and operations.

When you build that discipline into how you work, you do not just stop problems from recurring. You raise the standard for how your supply chain performs.

Are your problem-solving efforts driving systemic change, or simply containing recurring issues?